Thermostat with valve

Advantages

Thermostatic regulation of combustion has many advantages compared to classic manual regulation by opening and closing the ashtray:- easy and smooth temperature control

- optimal temperature according user choice is maintained, increased comfort of human operator

- prevention of heating device overloading and extension of its lifetime

- automatic regulation of air supply, optimization of combustion process and reduction of fuel consumption

- increasing of combustion process efficiency and continuous burning during the whole night

Description

Capillary systems filled with heat-transfer oil are used for thermostats which limits the use up to 300 °C. Range of working temperature is the crucial parameter for selection of capillary system.20 ÷ 90 °C

Capillary system in copper design

20 ÷ 300 °C

Capillary system in stainless steel design

Bimetallic systems can be used when higher temperature up to 500 °C is required.

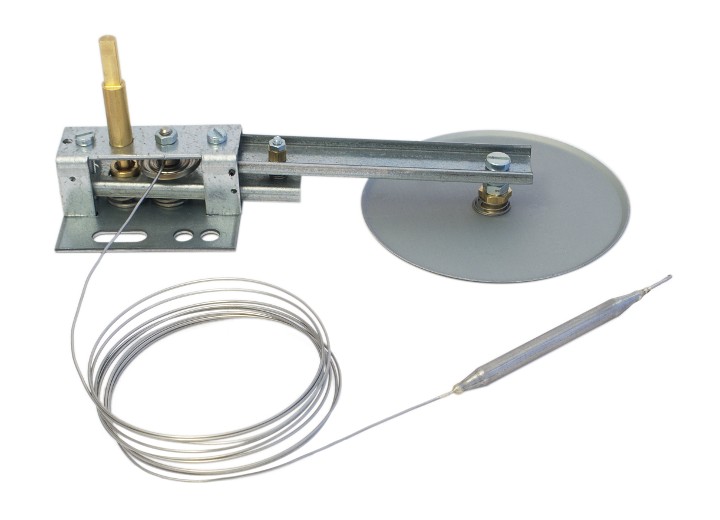

Temperature can be set using regulation screw on the thermostat. Thermostats can be equipped with regulation screws with various pitch for optimal performance of the heaters. One of following control designs can be chosen according to heater construction:

- top control (capillary or bimetallic system)

- bottom control (capillary system)

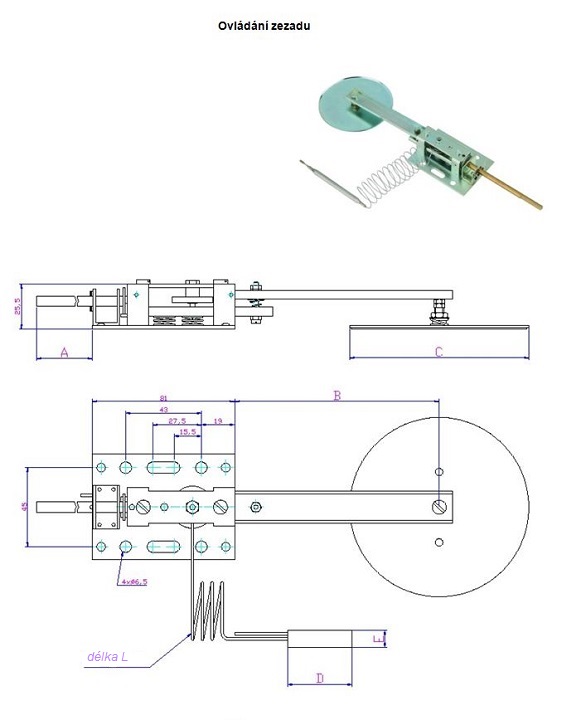

- rear control (capillary system)

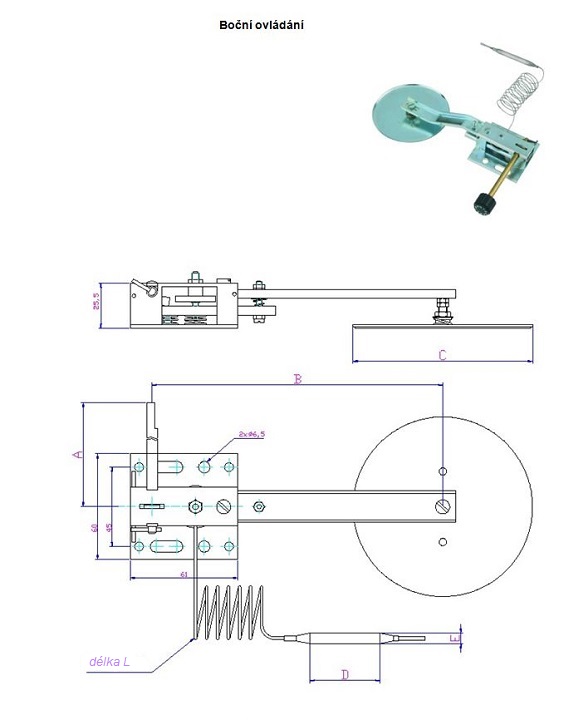

- side control (capillary system)

Dimensional drawings

(example of capillary thermostat with valve bottom control)

Thermostats with valve are supplied directly to manufacturers of solid fuel heaters. Construction (capillary length; design, shape and length of arm; size and shape of valve; mechanical system itself and its controlling; length of regulation screw) is always chosen according to customer needs.

Today we offer more than 200 types of these thermostats. We are ready to provide you free consultation.